At ISS Billings Montana, we are your trusted partner for unparalleled expertise in industrial valve repair solutions and sales. Our comprehensive services are designed to meet the most demanding industrial requirements, ensuring your operations run smoothly and efficiently.

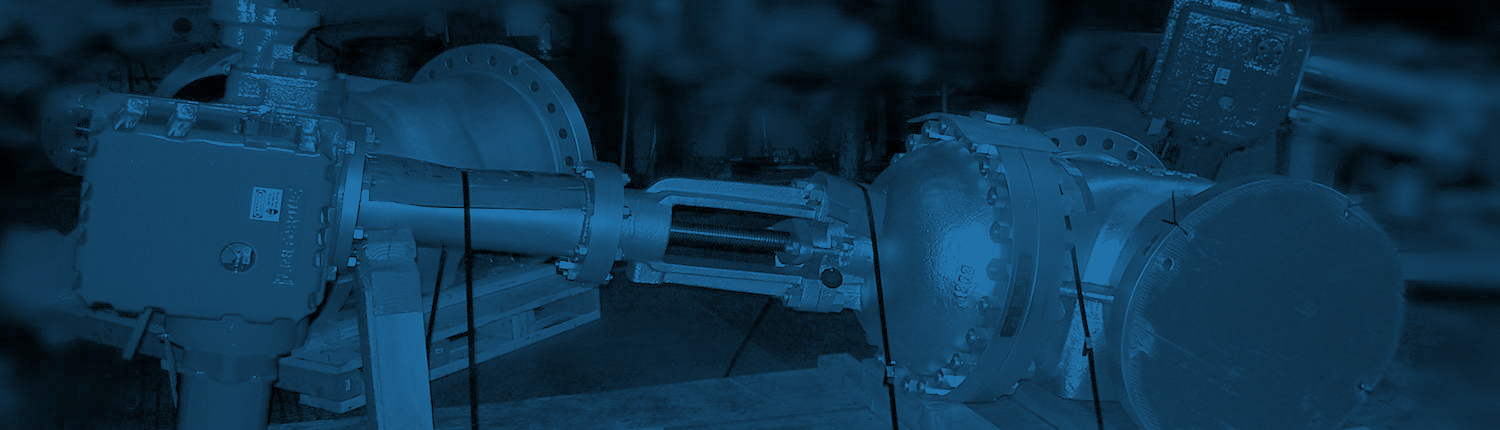

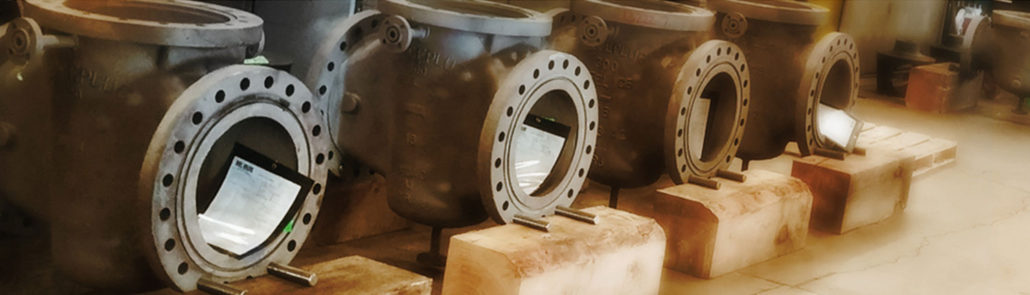

Our factory authorized repair center offer full-service repairs, reconditioning, modifications, testing and inspection services for all brands, types, and sizes of valves and actuators.

- Ball Valves

- Butterfly Valves

- Check Valves

- Control Valves

- Gate Valves

- Globe Valves

- In-line Valves

- Manual Valves

- Mixing Valves

- MOV Valves

- Plug Valves

- Pressure Relief

- Safety Valves

- Switch Valves

- Vent Valves

- Electric Actuators

- Hydraulic Actuators

- Pneumatic Actuators