At ISS Brighton Colorado, we are your trusted partner for unparalleled expertise in the industrial electric motors, pumps, and valve repair solutions. Our comprehensive services are designed to meet the most demanding industrial requirements, ensuring your operations run smoothly and efficiently.

As a stocking distributor of leading brands such as Baldor, Worldwide, GE, US Electric, Marathon, A.O. Smith, and Louis Allis, we guarantee quality and reliability.

In-house Machine Shop Services

Our Capabilities

Advanced Machining Technology

Our machine shop is outfitted with advanced technology capable of handling complex machining tasks. From CNC milling and turning to grinding and drilling, we have the capabilities to work on a diverse array of materials with high precision and efficiency.

Custom Machining and Fabrication

Understanding the unique requirements of our clients, ISS Brighton Colorado specializes in custom machining and fabrication services. Whether it’s a one-off part or high-volume production, our team works closely with clients to design and manufacture components that meet exact specifications.

Reverse Engineering and Prototyping

With our reverse engineering services, we can replicate hard-to-find or discontinued parts, ensuring your machinery keeps running without interruption. Our prototyping services are ideal for testing new designs before moving to full-scale production, minimizing risks and optimizing performance.

Shop Machining Capabilities

with specifics on size and types of machinery.

Shop Machining Excellence

With capabilities including a 38’’ swing by 12’ long turning capacity and vertical milling up to 38’’ swing by 72’’ length, our shop is equipped to handle intricate machining tasks with precision.

Certified Welding

Offering TIG, MIG, stick, and hard facing by certified welders, we uphold the highest standards of quality and durability in every wel

Electric Motor and Pump Repair Facility

Our electric motor repair shop is outfitted with an 8ft VPI, dynamic balancing up to 15000 lbs, and testing capabilities up to 4160 Volts. Our pump repair facility is adept at handling vertical turbine, submersible, centrifugal, and progressive cavity pumps, ensuring your equipment operates at peak performance.

At ISS Brighton Colorado, we are committed to innovation, quality, and customer satisfaction. Our well-equipped machine shop supports custom machining, reverse engineering, and facilitates repairs, setting us apart as a leader in the industry. Partner with us for solutions that drive your business forward.

Contact us:(866) 264-3605 | denver@bay-valve.com

For EMERGENCY SUPPORT with industrial maintenance or repair, call ISS Brighton Colorado now.

Let our expertise and commitment to quality ensure your operations are back up and running smoothly.

Contact us:

(866) 264-3605

denver@bay-valve.com

For EMERGENCY SUPPORT with industrial maintenance or repair, call ISS Brighton Colorado now.

Let our expertise and commitment to quality ensure your operations are back up and running smoothly.

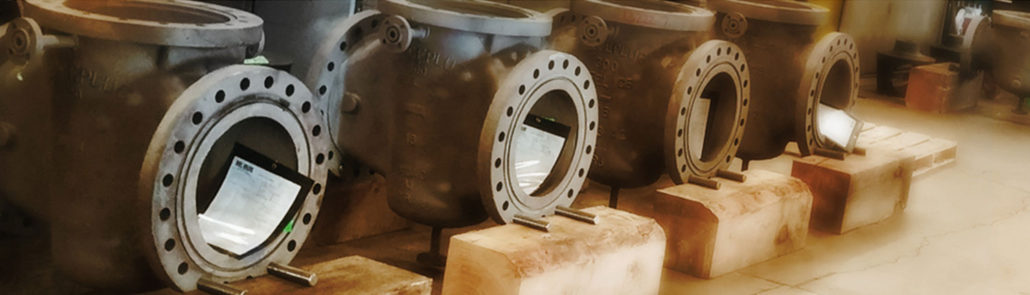

Valve Maintenance and Repair

with specifics on size and types of machinery.

Expert Inline Valve Repair Services

Our core competencies lie in our advanced portable machining equipment, specifically designed for inline repair services of manual and safety valves. This capability ensures that we can provide high-quality repairs with minimal downtime, directly at your facility.

Portable Lapping for Manual Valves

ISS Brighton Colorado specializes in the use of portable lapping technology, which is crucial for the precise repair of manual valves. This technique enhances the sealing surfaces, ensuring optimal valve performance and longevity.

Safety Valve In-Line Service

Safety is paramount in industrial operations, which is why our portable machining equipment is also adept at servicing safety valves in line. This ensures that your safety valves are always in peak condition, ready to protect your operations and personnel.

On-site Valve Machine Shop Service

Our 53’ and 40’ service trailers deliver full machining and welding services directly to your site, supported by portable lapping and machining equipment for in-line valve repair and EVT testing equipment for safety valves.

EVT Testing for Safety Valves

Further solidifying our expertise in safety valve maintenance, we employ EVT testing equipment for in-line testing. This advanced testing method provides accurate assessments of safety valve performance, ensuring compliance with industry standards and regulations.

ISS Brighton Colorado stands as a leader in valve repair, electric motor repair, pump repair, machine shop services, and especially in valve repair and maintenance. Our use of advanced portable lapping and machining equipment, along with EVT testing for safety valves, highlights our dedication to providing top-tier service and ensuring the safety and efficiency of your operations.

Electric Motor Maintenance and Repair

Enhancing Performance and Lifespan

Sales and Service for Electric Motors

Ensuring the health of your electric motors is essential for maintaining peak performance and reliability within your operations. A regimen of predictive and preventative maintenance, along with timely repairs, is crucial for minimizing downtime and extending the life of your motors.

Importance of Lubrication in Electric Motors

A significant factor in electric motor failures, accounting for roughly 75%, is bearing failure, which underscores the importance of proper lubrication. Adhering to manufacturer-recommended lubricants and schedules, tailored to specific site conditions, is vital for maximizing the lifespan of electric motors. This practice not only protects the motor’s internal components but is also a key element of a thorough electric motor maintenance program.

Bearing Maintenance: Keeping Electric Motors Running

The health of motor bearings directly impacts the efficiency of electric motors. Engaging in predictive maintenance allows for the extension of bearing life by identifying and addressing issues before they lead to failure. Integrating bearing replacement into a regular maintenance schedule is essential for avoiding expensive repairs and ensuring continuous operation. Proper timing and expert installation of bearings can significantly reduce the need for further machinery work or adjustments.

The Role of Cleanliness in Motor Efficiency

The accumulation of contaminants within electric motors can severely affect both their electrical and mechanical performance. Regular cleaning transcends mere visual appeal; it is fundamental for maintaining efficiency and preventing failures due to contamination.

ISS Brighton Colorado is dedicated to providing the highest quality services in electric motor repair, pump repair, machine shop capabilities, and valve repair. Our expertise and commitment to customer satisfaction set us apart as industry leaders.

Comprehensive Support Services

Electric Motor and Pump Repair Facility

We offer more than just machining; our comprehensive support services encompass assembly, testing, and finishing, aiming to be your one-stop solution for all machining needs. This approach minimizes lead times and maximizes quality and service.

Troubleshooting Electrical Testing and Diagnostics

Electrical Testing and Diagnostic Services

At ISS Brighton Colorado, we understand the complexities of electrical systems within industrial settings. Our comprehensive troubleshooting, electrical testing, and diagnostic program leverages a broad spectrum of on-line and off-line technologies, ensuring we can accurately monitor and diagnose issues across a wide range of electrical components. From motors and generators to cables and switchgear, our array of technologies and expert technicians are equipped to handle your electrical needs.

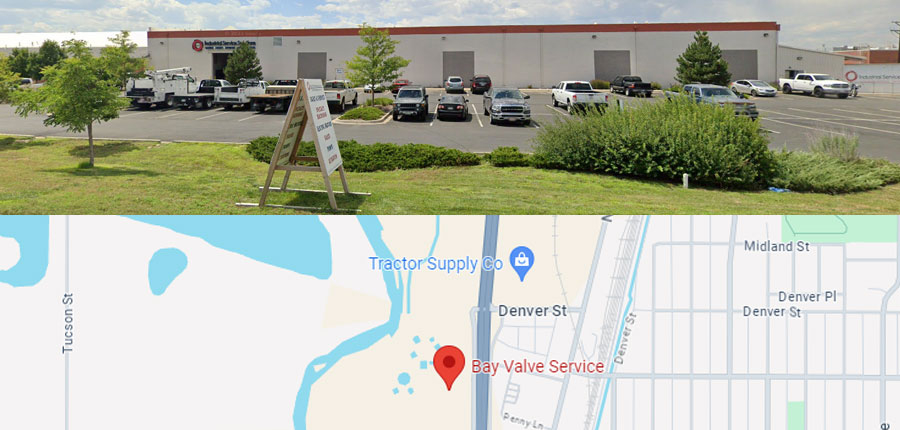

About ISS/Bay Valve Brighton

Machine Shop Services

Valve Maintenance and Repair

Electric Motor Maintenance & Repair

Contact Details

221 N Kuner Rd. Denver CO 80601

(866) 264-3605

(303) 364-2227

Glenn Stephenson:

denver@bay-valve.com.

Certifications and Accreditations

We are quipped to serve various industries like power, oil-and-gas, mining, and more, continues the legacy of excellence established by Bay Valve Service.